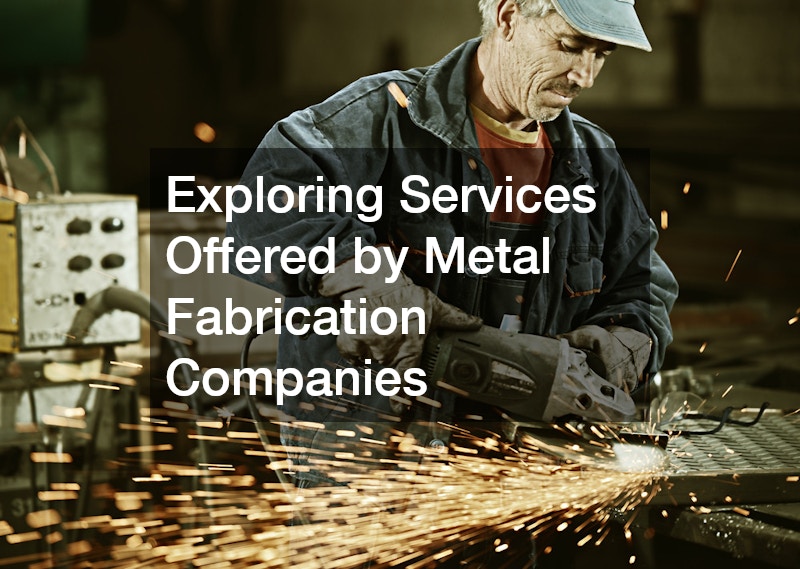

This article delves into the various services provided by metal fabrication companies, exploring common inquiries and industry practices. From cutting and bending to welding and assembling, these companies play a vital role in shaping raw materials into usable components for countless industries. Their expertise ensures accuracy, durability, and efficiency in every project, whether it involves creating custom parts, large-scale structures, or detailed prototypes.

Metal fabrication companies also stay up to date with evolving technologies, such as laser cutting and CNC machining, which allow for greater precision and faster turnaround times. Beyond technical skills, they often provide design assistance and material recommendations, ensuring clients get the best possible results. Whether you are a business owner seeking reliable manufacturing support or an individual looking for custom metalwork, understanding the full scope of services offered can help you make more informed decisions when selecting a fabrication partner.

What is Metal Fabrication?

Metal fabrication is the process of constructing machines and structures from raw metal materials. It involves a variety of processes, including cutting, bending, welding, and assembling. These processes are essential for creating everything from simple parts to complex assemblies that are vital in numerous applications. Metal fabrication is crucial for transforming raw materials into functional components that are used across various industries.

The fundamental techniques underpinning metal fabrication include machining, welding, and metal forming. Machining involves the use of tools to cut away at raw metal to achieve the desired shape, whereas welding is used to join two or more pieces together. Metal forming, on the other hand, changes the shape of the metal without removing material, often via processes such as bending or stamping.

Understanding metal fabrication is pivotal for industries that rely heavily on metal structures and components. Professionals in sectors like automotive, aerospace, and manufacturing can take advantage of these services to produce parts with precise specifications. This understanding helps stakeholders in making informed decisions when selecting metals and processes suitable for their specific applications.

What Services Do Metal Fabrication Companies Typically Offer?

Metal fabrication companies offer a wide range of services designed to meet the needs of their clients. These typically include services such as sheet metal fabrication, welding, cutting, and assembly. Sheet metal fabrication allows for the creation of components from flat sheets of metal, while welding is essential for joining multiple parts together. Additional services may involve machining, finishing, and even custom designs tailored to client specifications.

Moreover, the finishing process is critically important in metal fabrication. This involves treatments that enhance the appearance and durability of the metal, such as powder coating, plating, and polishing. These processes not only improve the aesthetic appeal but also provide protection against corrosion and wear, extending the lifespan of the metal components produced.

Specialized services may also be offered depending on the company’s capabilities. Some metal fabrication firms have advanced technological solutions for 3D printing, laser cutting, or CNC machining. These technologies enable them to execute high-precision tasks and meet the demands of more sophisticated and complex projects.

What Industries Utilize Metal Fabrication Services?

Metal fabrication is integral to numerous industries, including automotive, aerospace, construction, and manufacturing. Each of these sectors relies on fabricated metal components for essential functions. In the automotive industry, for example, metal fabrication is used for parts like chassis, engine mounts, and body works. Precision in fabrication is crucial to ensure safety and efficiency in vehicle performance.

Aerospace also heavily depends on metal fabrication processes. The industry requires light-weight yet strong components that can withstand extreme conditions. Metal fabricators assist in producing everything from structural components to intricate aircraft parts, demonstrating their crucial role in ensuring that equipment meets strict regulatory standards and performance benchmarks.

In construction, metal fabrication plays a key role in creating building frameworks, support structures, and decorative elements. As cities grow and infrastructure demands increase, the need for efficient and reliable metal fabrication services becomes even more pronounced. Thus, understanding which industries utilize metal fabrication services helps in recognizing the broader implications of this essential process.

How to Choose the Right Metal Fabrication Company?

Selecting the appropriate metal fabrication company can significantly impact the success of your projects. It is essential to consider the company’s expertise and experience in the specific type of fabrication required for your job. An experienced fabricator will have a proven track record and a portfolio demonstrating their capabilities. This insight allows you to gauge whether they are fitting for your unique requirements.

Additionally, evaluating the technology and machinery used by the fabrication company is crucial. Cutting-edge technology can lead to better precision and quality in the final product, so understanding the tools and processes they utilize will help in making an informed choice. Companies that invest in modern machinery may provide enhanced capabilities and more efficient production timelines.

Finally, communication and customer service are paramount in the selection process. A company that maintains clear communication and provides excellent customer service is important for discussing ideas, changes, and potential setbacks throughout a project. Building a partnership based on effective communication can lead to better collaborative results and a smoother fabrication process.

Summarizing the importance of metal fabrication services and encouraging consideration of professional companies for specific needs.